Printed circuit boards come in many forms with custom designs for unique functions and applications. The general purpose of printed circuit boards is rather simple and involves connecting different components of a device for its operation. They assist in the functioning of devices and can be configured in highly complex ways to meet specialized applications. Read More…

At TTM Technologies Inc., we dedicate ourselves to advancing the design and manufacture of high-performance printed circuit boards that power innovation across industries. We bring together engineering precision, advanced materials expertise, and a deep understanding of complex electronic systems to deliver solutions that meet the most demanding requirements.

At Flex Ltd., we take pride in being a global leader in advanced manufacturing and design innovation, shaping the future of technology through our expertise in printed circuit boards and electronic systems. We view every project as an opportunity to help our customers transform bold ideas into market-ready products, providing the precision, scale, and flexibility that modern industries demand.

At Amphenol Printed Circuits, we take pride in designing and manufacturing advanced printed circuit board solutions that power the world’s most demanding technologies. As part of the global Amphenol family, we bring together decades of engineering expertise and innovation to deliver high-performance, high-reliability interconnect solutions across industries such as aerospace, defense,...

At Creation Technologies, we are committed to transforming ideas into high-quality electronic solutions through our deep expertise in printed circuit board design and manufacturing. We take pride in being a trusted partner to original equipment manufacturers who rely on us to bring their complex products to life with precision, reliability, and speed.

At Summit Interconnect, we take pride in being one of North America’s leading printed circuit board manufacturers, bringing advanced engineering, precision manufacturing, and innovation together to serve the most demanding industries. We specialize in producing complex multilayer, rigid-flex, and HDI printed circuit boards designed to perform in critical applications where reliability and...

More Printed Circuit Board Assembly Companies

PCBs are designed to provide channels and pathways for electricity and signals to be conveyed from one device to another. Of the many components of electrical equipment, PCBs are the most common. They are a highly efficient and complex part of electrical devices. PCBs can easily be built, shaped, and configured for any type of application. In general, there is a type of PCB for any form of electrical connection, regardless of a connection’s complexity, flexibility, and size.

Types of Printed Circuit Boards

The differences between PCBs are based on several factors, aside from their function. The initial factors that differentiates PCBs are their size, shape, the stress of an application, required mechanical properties, and electrical load. The most noticeable aspect of PCBs is their number of layers, which can be one single layer and go up to 4, 6, 8, and beyond layers. Although the substrate for most PCBs is a hard fiberglass material, there are PCBs that are built on flexible, expandable belts that can be wrapped around poles.

Multilayer PCBs

The design of multilayer PCBs includes several layers of the substrate that can be as few as three and greater than eight. The layers of a multilayer PCB are tightly sandwiched together with several double-sided conductive layers separated by insulation material. For stability, the layers are bonded together using different types of materials or are laminated under high pressure and temperature. The tight seal between the layers eliminates air gaps and provides extra strength.

The design of multilayer PCBs allows for the use of more complex circuitry in a smaller footprint. The many layers of multilayer PCBs add to their strength and the protection of circuitry. They can handle heavy loads with speed and efficiency. Instead of having several single layer PCBs, the work of connecting is combined into a single connection point. As may be assumed, the many benefits of multilayer PCBs add to their cost.

The factor that has to be examined when purchasing multilayer PCBs is how the layers of the PCB connect. There are three types of holes, called vias, that manufacturers use to connect the different layers, which are blind, through hole, and buried. Each type is strategically located to provide access to the different layers.

Single Layer PCB

The work of a single layer PCB occurs on one side of the PCB. The reverse side involves the inclusion of other components. Single sided PCBs were developed in the 1930s as a replacement for the cumbersome circuit boards of that era. They were first introduced to the public in the 1950s. Of the various forms of PCBs, single sided PCBs are the simplest and least complex. They require fewer resources and have very low density, making them a cost-effective industrial solution. Single layer PCBs are produced in high volume, which further lowers their cost.

The high numbers of single sided PCBs make them the most widely used of the PCBs. Although they have a simple design, single sided PCBs can be used in unison for complex and intricate applications. This factor helps in lowering the cost of final products. The use of single side PCBs for complex tasks has to be carefully considered when designing a product.

Double Sided PCBs

Double sided PCBs are a popular choice for complex designs. What differentiates double sided PCBs from single sided PCBs is the ability to mount components on both sides of the board. Routing traces can be closer and can alternate between the sides. The connection between the sides is by holes, or vias, that are drilled in locations on the board to provide easy connections. In some cases, holes are not drilled and the two sides operate independently. This type of design is determined by the use of the PCB.

The popularity of doubled sided PCBs is due to their ease of use. They have increased circuit density due to the second layer that increases the board’s capacity. The greater capabilities of double sided PCBs enables them to be used for complex applications. The wide use of double sided PCBs is due to their size, which is smaller than other types of boards.

Rigid PCBs

Rigid PCBs are solid and inflexible and cannot be bent, reshaped, or flexed. They have solid substrate, copper, solder mask, and silkscreen layers that are joined using heat and an adhesive. Rigid PCBs come in all forms of PCBs, single, double, or multilayered. They are manufactured to meet the specific requirements of an application and cannot be modified once manufactured.

Like single sided PCBs, rigid PCBs are produced in large quantities, which lowers their cost. Their wide use is due to their durability and long wearing dense circuitry. Rigid PCBs are used in applications where components are fixed in place and have to endure heat and stress.

Flexible PCBs

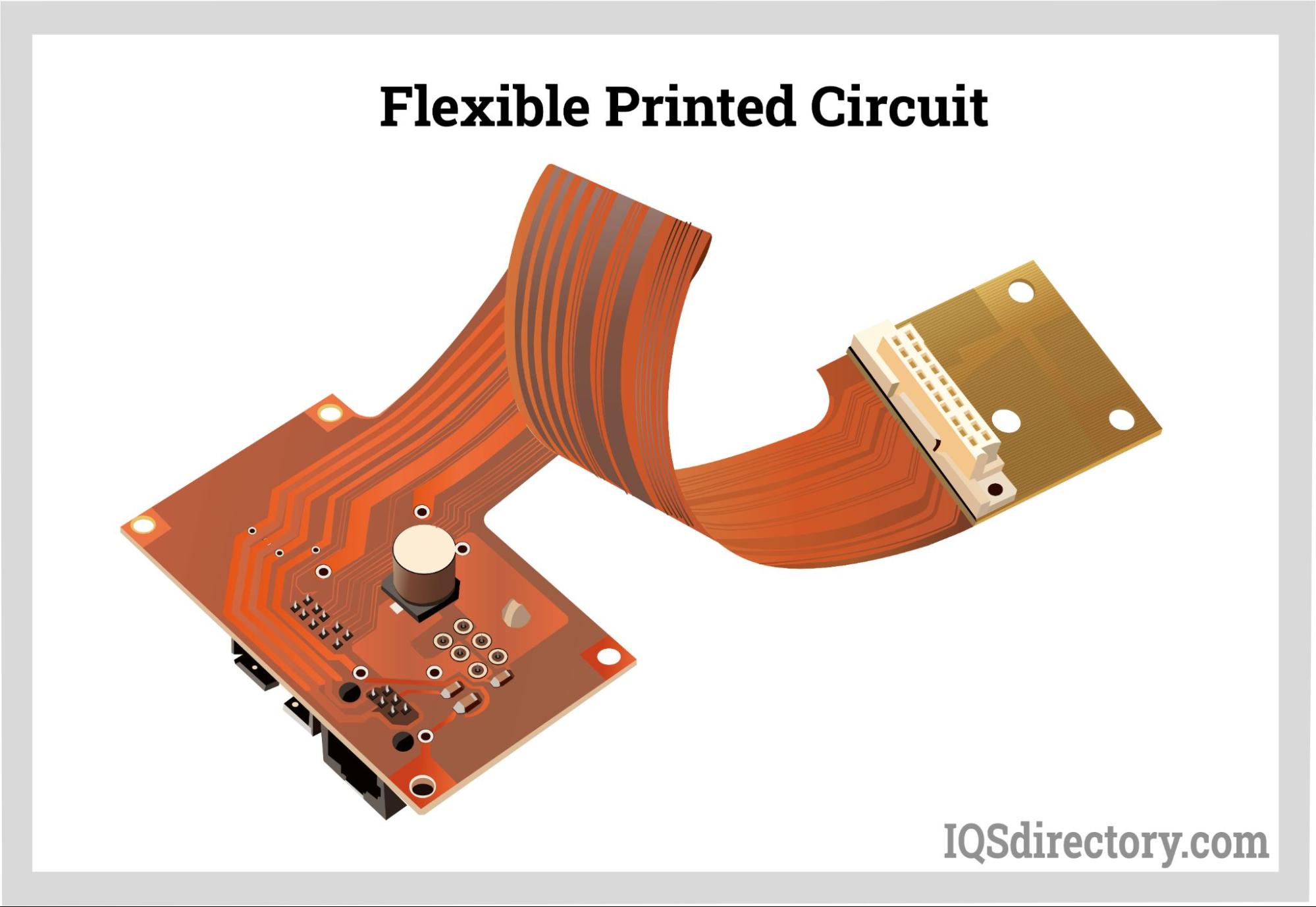

The substrate of flexible PCBs is pieces of thin plastic that can be rolled, tied, and stretched. The structure resembles a piece of tissue made of plastic. Traces and components are mounted on the flexible material. Flexible PCBs help designers create electronics capable of accepting any shape of circuit board without concerns about the size of the space for the circuit board. They can be contoured, bent, and shaped to fit the requirements of any space.

Unlike other forms of PCBs, flexible PCBs are manufactured using less material and can be easily packaged. They are easy to replace and are a cost-effective solution. The uses of flexible PCBs are endless since they can fit into any application.

Rigid-Flex PCBs

A hybrid form of PCB is the rigid-flex PCB, which combines the many positive features of rigid PCBs and flexible PCBs. The flexible layers are buried in the board and penetrate through the rigid section of the structure. As with flexible PCBs, rigid-flex PCBs can be folded, twisted, bent, and stretched to create a shape that best fits an application. They provide exceptional efficiency and are used in applications where weight needs to be limited and space is at a premium.

Since rigid-flex PCBs are thinner, they are ideal for products that are not wide or thick. Their low weight enables them to be used in small handheld products. The thin layers of copper and the elimination of adhesives through the use of laminates makes rigid-flex PCBs smaller, thinner, and lighter. Rigid-flex PCBs are ideal for modern products due to their small size. They can be found in many handheld devices and components. A common use of rigid-flex PCBs is in aircraft and rockets, which have limited space and require high efficiency and lightweight.

The types of printed circuit boards described above are the main types that are commonly used in modern electronics. PCB manufacturers have proprietary PCBs that they manufacture for certain products. These particular PCBs are the result of the collaboration between manufacturers and their clients. In addition, there are several other types of printed circuit boards, such as high density (HDI), metal core, lighting PCBs, blank, and custom designed PCBs for special applications.

History of Printed Circuit Boards

The history of printed circuit boards (PCBs) spans over a century, evolving from simple electrical connections to the backbone of modern electronics. In the early 1900s, inventors like Albert Hanson in Germany (1903) conceptualized laminated boards with conductive paths for telephone systems, laying the groundwork for PCBs. By the 1920s, Charles Ducas in the U.S. patented a method of creating conductive paths on insulating material, calling it a “printed circuit.”

The real breakthrough came during World War II. In 1943, Austrian engineer Paul Eisler, working in the UK, developed the first functional PCB for a military radio, using copper foil on a non-conductive base. This innovation enabled mass production of reliable electronics. The U.S. Army adopted the technology in 1948 for proximity fuses, standardizing PCB manufacturing.

In the 1950s, the auto-assembly process emerged, where components were inserted into boards and soldered, streamlining production. The 1960s introduced multilayer PCBs, allowing complex circuits in compact spaces, crucial for computers and aerospace. Surface-mount technology (SMT) in the 1980s further revolutionized PCBs by eliminating through-holes, enabling smaller, denser designs for consumer electronics like mobile phones.

Today, PCBs are integral to nearly all electronics, with advancements like flexible PCBs and high-density interconnects (HDI) supporting wearable tech and IoT devices. The global PCB market was valued at $75.83 billion in 2023, reflecting their critical role in technology.

Industries that use Printed Circuit Boards

Printed circuit boards (PCBs) are foundational components across numerous industries due to their role in enabling compact, reliable, and efficient electronic systems. Here’s a breakdown of key industries that rely on PCBs as of May 15, 2025:

-

- Consumer Electronics: PCBs power devices like smartphones, laptops, TVs, and gaming consoles. Surface-mount technology and high-density interconnects (HDI) allow for miniaturized, high-performance circuits in products like the latest iPhones or gaming systems, with the global consumer electronics market driving PCB demand (valued at $75.83 billion in 2023).

- Automotive: Modern vehicles use PCBs in engine control units (ECUs), infotainment systems, sensors, and electric vehicle (EV) battery management systems. Advanced driver-assistance systems (ADAS) and autonomous driving tech, like Tesla’s Full Self-Driving, rely on multilayer PCBs for real-time processing.

- Medical Devices: PCBs are critical in equipment like MRI machines, pacemakers, and diagnostic devices. Flexible PCBs enable wearable health monitors, such as glucose trackers, ensuring compact designs and reliability for patient safety.

- Aerospace and Defense: PCBs in avionics, satellites, and military systems (e.g., radar, communication devices) require high reliability under extreme conditions. The U.S. Army’s adoption of PCBs in 1948 for proximity fuses highlights their long-standing role in defense tech.

- Industrial Automation: Robotics, PLCs (programmable logic controllers), and IoT devices in smart factories use PCBs for control systems and sensors, supporting Industry 4.0 trends like automated assembly lines.

- Telecommunications: 5G infrastructure, routers, and base stations depend on PCBs for high-frequency signal processing. The rollout of 5G networks globally has spiked demand for advanced PCB designs.

- Energy Sector: Renewable energy systems, like solar inverters and wind turbine controls, use PCBs for power management. Smart grids and energy storage solutions also integrate PCBs for efficient energy distribution.

- Lighting: LED technology, used in residential, commercial, and automotive lighting, relies on PCBs for power regulation and heat dissipation, supporting energy-efficient solutions.

PCBs’ versatility ensures their use in virtually any industry involving electronics, with ongoing innovations like flexible and biodegradable PCBs expanding their applications further.